CNC Press Brakes

Press Brakes

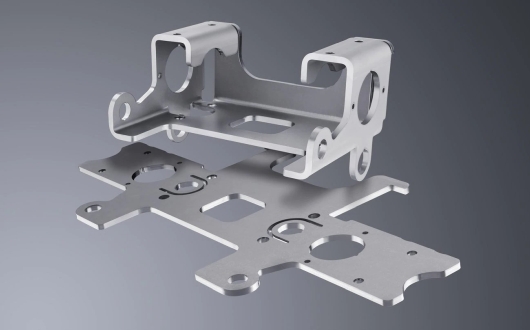

Press forming - bending is performed with the use of high-performance Trumpf TruBend 3100 and Trumpf TruBend 5320 press brakes. The final shapes can be achieved using the procedures of free bending, press forming, folding and final shaping.

We are able to work with the sheet metal of up to 4,000 mm length.

Moreover, our company is able to create a wide range of products, starting with furniture fittings and mechanisms and ending with large structures for sites, dual carriageways, and concrete mixing plants.

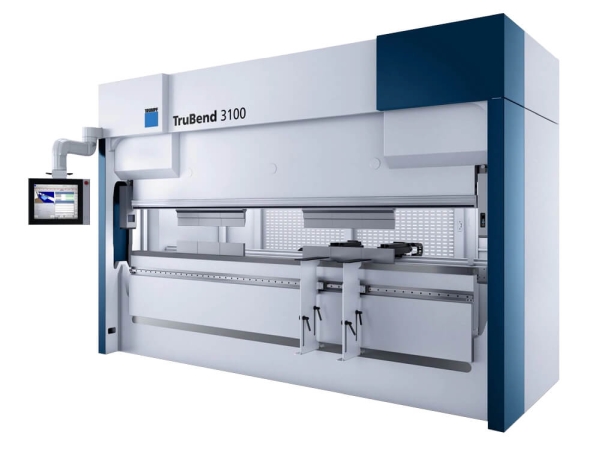

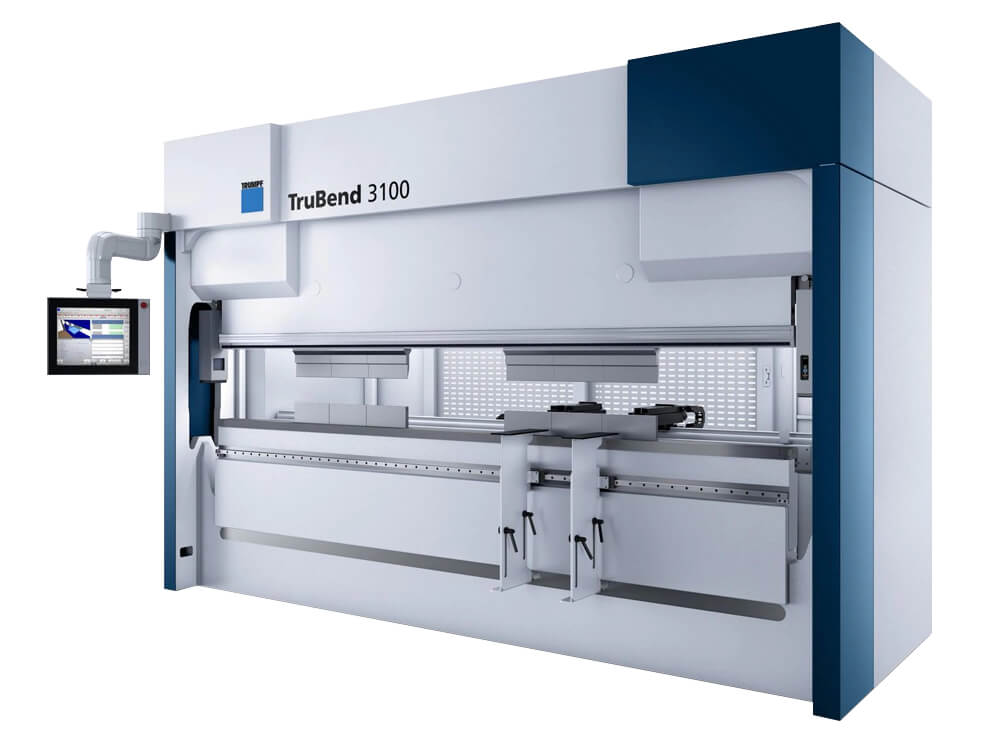

Trumpf TruBend 3100

Economic standard machine

TTruBend Series 3000 is the combination of the highest TRUMPF quality, easy operation and attractive price-performance ratio. Thanks to that, it can economically produce even at a low load and ensure precise results and the highest safety standard. Thanks to the perfect coordination of all their components, the TruBend Series 3000 machines are the fastest press brakes in their category.

Trumpf TruBend 5320

Perfect and fast bending

The TruBend Series 5000 is TRUMPF’s most successful press brake worldwide. Innovative features such as lower tool displacement and the 5-axis backgauge system provide complete freedom for your applications. Numerous innovations, including the revolutionary simple and intuitive control concept as well as modern ergonomic solutions, make the operator’s work easier.

Trumpf press brake

Trumpf TruBend 3100

| Moulding force | 1000 kN = 100 tons |

| Bending length | 3060 mm |

Trumpf press brake

Trumpf TruBend 5320

| Moulding force | 3200 kN = 320 tons |

| Bending length | 4420 mm |